Grinding media steel balls, hardened steel .

Stainless steel balls and other shapes are used for grinding applications where absolutely no iron contamination is ... Ball Mill used for grinding, milling, ...

WhatsApp)

WhatsApp)

Stainless steel balls and other shapes are used for grinding applications where absolutely no iron contamination is ... Ball Mill used for grinding, milling, ...

ball milling in uses. Allied High Tech XPrep How to safely and effectively use a ball mill to grind pyrotechnic chemicals and black powder. Chat Now.

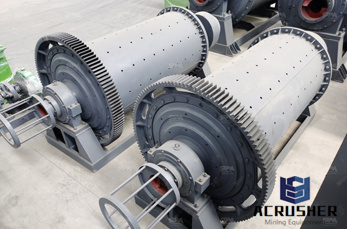

Our company produces raymond mill, high pressure grinding mill and other milling equipment, as well as ball mill, rod mill, cement mill and other grinder mills ...

Ball Milling method for synthesis of nanomaterials. Posted on June 15, ... As the name suggests, the ball milling method consists of balls and a mill chamber.

Synthesis of Nanomaterials by High Energy Ball Milling ... It is a ball milling process where a powder mixture ... Planetary ball mill is a most frequently used ...

Functionalized graphene nanoplatelets from ball milling for 1 energy applications Xueliu 1 Fan, Dong Wook Chang2, Xuli Chen1, JongBeom Baek3 and Liming Dai

The increase in the ballmilling time also caused a continuous decrease in the sample grain size until 48 h, ... 209220 215 uses the explicit central difference time to ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

CNC Milling: Introduction to cutting tools . ... A ball nose end mill, also ... Noncenter cutting mills are used only for side milling. When choosing a ball end mill ...

How to Use a Ball Mill Safely and Effectively ... ball milling is the best way for the amateur fireworker to reduce particle size in ... whatever charcoal one uses.

Why is the Bond Ball Mill Grindability Test ... Mill Work Index which expresses the resistance of a material to ball milling. ... This paper uses knowledge from

ball milling in uses. Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

Design and Optimization of Ball Mill for Clinker ... It appears to take almost 60 hours ball milling to get 25 nm ... work,laboratory ball mill uses 3 ...

Ndoped graphene was prepared by ball milling of graphite with melamine. It was found that ballmilling reduced the size of graphite particles from 30 to 1 μm and ...

Ball Nose Milling Heads with TS Threaded Adaptation Carrying Tangent Straight Edge Inserts for SemiFinish Profiling . BCMM Ball Nose Endmills with FLEXFIT Threaded ...

Planetary Ball Mills ... Highspeed and versatile. ... Extremely highspeed milling down into the nano range ; Up to 1100 rpm ;

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . Ball and Pebble Mills: The expressions "ball milling" and "pebble milling" are

Find here details of companies selling Ball Mills, for your purchase requirements. Get latest info on Ball Mills, suppliers, manufacturers, wholesalers, traders with ...

A ball mill is a type of grinder or mill used to mill the materials into fine powder. This ball mills are especially useful for grinding hard materials.

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process SeongHyeon Hong*, DongWon Lee, ByoungKee Kim Department of Materials ...

Ballmilling in liquid media: Applications to the preparation of anodic materials for lithiumion batteries

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Choose from our wide variety of grinding media for crushing and grinding in a mill. We carry ceramic grinding media, milling balls for wet and dry grinding

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes.

WhatsApp)

WhatsApp)